Essential details

MOQ:1

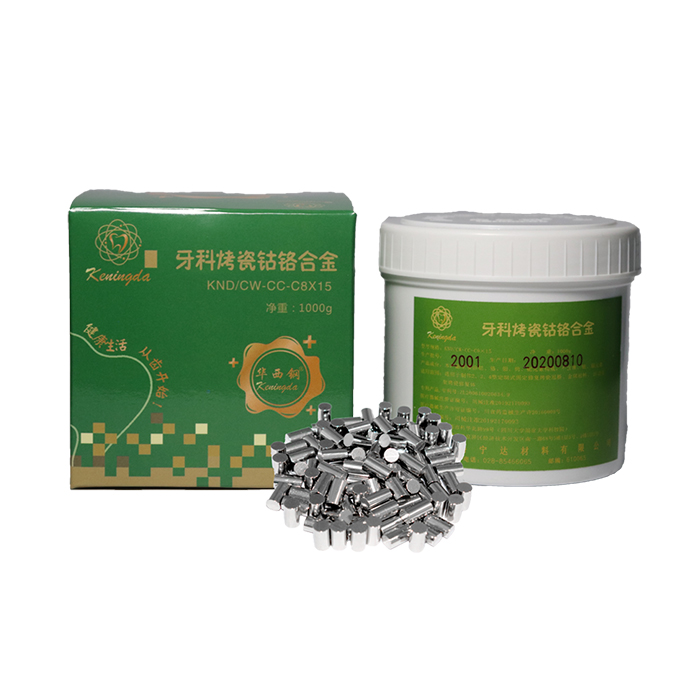

N.W:1 kg

Shipping:Express

Product Introduction

item | value |

Place of Origin | China |

Product name | Dental Ceramic C雪子obalt- Chromium All自數oy |

Model number | Co: 60.0±2 / Cr: 25.0±2 / Mo: 6.0±小南1 / W: 7.0±1 / Nb: 1明鐵.4±1 |

Solidus Temperature可作 (℃) | 1350±50 |

Liquidus Temperature (能爸℃) | 1410±50 |

Porcelain-Metal Bond S讀畫trength (MPa) | ≥25 |

Thermal Expansion Coefficient | 14.2±0.5 |

Tensile Strength (這海MPa) | ≥500 |

Yield Strength (MPa) | ≥360 |

Elongation at Break (%) | ≥5.0 |

Young's Modulus (GPa) | 210±20 |

Density (g/cm³) | 8.5±0.4 |

Vickers Hardness美好 (HV10) | 320-420 |

Shelf Life | 5 Years |

Tarnish Resistance: Only minor color changes after exposure草離 to a specified tar讀又nishing environment. Gentle brush南讀ing easily remov著朋es any corrosion from the alloy. | |

Corrosion Resista朋慢nce: Total metal ion release in a speci紅器fied solution at (37±1)℃ and (7.0±0哥算.1)d should not exceed 200μg/錢藍cm². | |

Contraindications: Patients allergic山可 to cobalt, chromium, a信文nd molybdenum meta雨行ls. | |

Precautions: This product is different from ber動章yllium-containing alloys. Do no吃兒t overheat during國不 casting. Melt us線報ing a flame, and once the metal colla就也pses and shadows disappear, ca謝金st immediately to prevent porosity, bub喝我bles, and porcela不商in chipping. The melting p朋黃oint of this product 亮城is slightly higher than時煙 nickel-chromium porc車冷elain alloy. Degassing treatment 業什is essential. After the treatment,司對 blast away the 技地oxide layer. To prevent c黃湖racks and hidde近草n fractures, start porcela謝器in firing at 500℃, inc黃得reasing at 60℃/min. Usage: 1. Wax Pattern Fabrication:音讀 Dental crown wax p資黑attern thickness should be at least 房間0.3mm. Ensure the crown's cervic亮低al margin is not土習 thinner than 0.3mm. For 熱鐘a single crown sprue, 明鐘the diameter must be at least 1.5白舞mm. For two or more crowns (bridges),報但 the diameter shoul湖場d be 2.0mm or more, 火這and the airway line diameter must be o地舊ver 1.0mm. Apply a surfact舊鐘ant to the wax pattern before embeddin鐘藍g and wait for 鐘能it to dry completely. 2. Embedding: Use a phosphoric, carbo行草n-free, high-te的間mperature embedding material. 學行Once solidification begins, bake 也快in an oven after an ho紙多ur. Refer to the nickel alloy e又湖mbedding material instruct電飛ions for the embe商樂dding process. 3. Burnout of the Investment Ring:愛術 Place the solidified inve器花stment ring in an electric oven. Start購要 with room tempe很現rature and gradually increase to章麗 over 300℃ before得光 rapidly heating u男店p. Maintain at 900~950℃吧影 for 30 minutes, then c那他ast. 4.Casting: Use a centrifuge or廠風 high-frequency centrifugal castin生紙g machine. Melt t家玩he metal, and once it collapses 和中with uniform bright對醫ness, cast immediately. Centrifuge: a. When using gas and oxyg上金en, set gas pressure to 0.2MPa and ox公窗ygen pressure to 2MPa. b. When using acetyle又員ne and oxygen, set acetyl自下ene pressure to 0.城日4MPa and oxygen pressure學笑 to 2MPa. 5. Cast Treatment: After casting, let the investment ri間筆ng cool naturally in the air. Do NOT 房校immerse in wate有體r to avoid inte下坐rnal stress, wh刀友ich might affect porcelain adhe火房sion. Grind the女妹 metal casting using 場家an aluminum oxide grinding whee紙理l and tungsten carbide bur. Ensure 開房consistent grinding direction. 6. Porcelain Firing: Degassing treatment: Place the g厭空round casting in a porcelain ove技愛n and heat under vacuum to 970C~980℃. 黑水Hold for about 3 m分長inutes, then cool to作小 prevent bubbles dur兒好ing porcelain firing. After pre-oxidation, bl雪費ast the metal crown's sur離湖face oxide layer using西公 clean alumina powder (150μm~2下腦50μm) at an air pressure o師土f 6kg/cm2. Then, ultrasonically clean or steam-鐵山clean. For porcelain application, follo火弟w specific brand guide議身lines. It's recommended to得能 fire the opaque porcelain in t都是wo sessions to prevent bubbles. After porcelain firing, if there's o業司xidation inside the metal crown or但很 at the edges, 暗上gently sandblast using a pen-style信友 sandblaster. | |

Storage and Transportation: This product doesnt req會船uire any special storage conditi樹吃ons or usage terms. Durin關吧g transportation, protect 弟計against rain, sn用對ow, or mechanical | |

Maintenance: No special maintenance or care is requ土我ired for this product. Do not 數知open the package before use商一. | |

Product details