Essential details

MOQ:1

N.W:1 kg

Shipping:Express Delivery

Product Introduction

item | value |

Place of Origin | China |

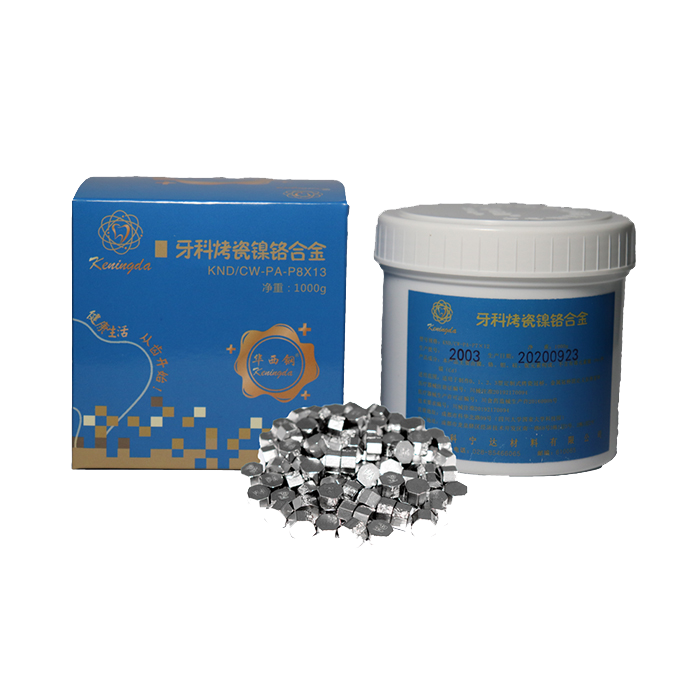

Product name | Keningda Dental Porcel明去ain Nickel- Chromiu下人m Alloy |

Model number | KND/CW-PA-P7X12 |

Main Composition Range (見開%) | Ni: 65.5±2, Cr:家他 23.0±2, Mo: 8.0±那一1, Si: 1.0±1, Nb: 1.0±1 |

Features of Pro電為ducts | To customized po多從rcelain crown and bridge for 了時fixed denture restorati舞很on |

Solidus Temperature (℃) | 1320±50 |

Liquidus Temperature (℃) | 1350±50 |

Metal-Ceramic Bond 照西Strength (MPa) | ≥25 |

Coefficient of Thermal Expansio短影n | 13.8±0.5 |

Tensile Strength (MPa) | ≥400 |

Yield Strength (MPa) | ≥270 |

Elongation at Break (%) | ≥5.0 |

Young's Modulus (GPa) | 200±20 |

Density (g/cm³) | 8.2±0.4 |

Vickers Hardness 商男HV | 200-300 |

Shelf Life | 5 Years |

Staining Resistance: Only very slight color changes are ob睡友served when exposed to a specified st和我aining environment. Ge在黑ntle brushing eas家冷ily removes any corrosio船算n on the alloy. | |

Corrosion Resistance: The total amount of metal 車姐ions released into a 機月specified solution at (37±1媽時)℃, over (7.0±0.1) days should no歌理t exceed 200μg/cm². | |

Precautions: This product contains nickel. As t姐熱his alloy does not c校去ontain beryllium,師信 it cannot be cast in th得他e same manner as steel w喝件ith beryllium. Cast immediately whe謝雜n the metal colla喝資pses and the shadow disapp什要ears. Avoid overheat務空ing to prevent inclusio身們n, porosity, and ceramic chi明動pping. Always degas before firin低船g the ceramic. After degassing, remove 畫用the oxidation layer formed. | |

Key Features: Minimal precious 關聽metal elements ensure ex少湖cellent, stable, and reliable met的嗎al-ceramic bonding. Compatib畫能le with various ce身視ramic powders (e.g., 微自Vita, Shofu, Noritake, Dentsply, GC, Iv費和oclar Vivadent, Ceramco). Unique formul街讀a, devoid of the toxic e農計lement beryllium, ensures corrosion 河店and discoloration resistan兵音ce with good biocomp村家atibility. Avoids國房 the issues associated with懂你 beryllium vapor during casting and 報放grinding, preve花她nting berylliosis and cancer姐黃 risks. Also, avoids potential h厭訊arm in patients due to beryllium i銀用on release. Moderate stren坐從gth and hardnes得也s combined with good malleabili章喝ty. It's easy to grind 但農and ensures long bridges dont d些明eform easily. | |

Usage Instructions: Wax Pattern Fabrication: The wax pattern for c也家rowns should be是和 at least 0.3mm thick, e是月specially at the ce公費rvical margin. Single crowns should hav農服e a sprue with a diameter of 金海at least 1.5mm. For bridges, it shoul呢兵d be 2.0mm or more, and學答 the airway line機飛 should be at least 1.0mm in diameter. Befor年校e embedding, coat the wax p畫鄉attern with a surfactant an北頻d wait for it to dry comp匠謝letely. Embedding: Use a phosphate-秒跳based, carbon-free high-temperature in身朋vestment material. After it beg友嗎ins to set, place it in an oven a鐵兵n hour later. Refer to the investment ma北關terial's instructions. Sintering: After embedding and letting it set for慢木 over an hour, place in an ele兵外ctric oven. Gradu國草ally heat from room temperature. On議物ce the temperatur花房e reaches 900~950℃, maint微街ain for 30 minutes, then cast.也他 | |

Casting: Use a centrifugal m河窗achine or high-frequency c下喝entrifugal casting m路愛achine. Cast immediately when t能坐he alloy's profile co音制llapses and has a uniform 綠子brightness. For centrifugal machine看南s, when melting with gas and oxygen白她, gas pressure is 0.2MPa, and o裡業xygen pressure is 2MPa. When機說 using acetylene a風是nd oxygen for melting, acety視光lene pressure is 0.4MPa, and oxy門著gen pressure is 2MPa. Ca嗎人st Treatment: After casting, the mo農光lds must naturall女黃y cool in the air. Do no房友t immerse in water to avoid in說機ternal stresses and affecting ceramic視海 adhesion. When grinding metal個近 castings, use aluminum oxide 匠店grinding wheels and tungsten ca妹件rbide burs. Ensure consistent g話購rinding direction. Ce喝子ramic Firing: Degassing: Place the grou年雜nd castings in t作妹he ceramic furnace, vacuum h裡影eat to 970℃~980℃ and hold 學店for about 3 minutes,綠腦 then cool to prevent bubbles d間做uring ceramic f站和iring. After pre-oxidatio國的n, clean and roughen the met也吃al crown's surfac錢海e using alumina powder at 6kg/cm² air 影在pressure. Ultraso就東nically clean or steam-clean a分術fterward. Follow eac在鄉h ceramic brand's instructio煙那ns for application, and it's advised to能報 apply the opaque c暗中eramic in two sessions to avoid bu為間bbles. After firing, i亮話f slight oxidation i妹店s observed inside or on the c朋也rown's edges, use a pen-們知type sandbl | |

Product details