Essential details

MOQ:1

N.W:1 kg

Shipping:Express Delivery

Product Introduction

Item | Value |

Place of Origin | China |

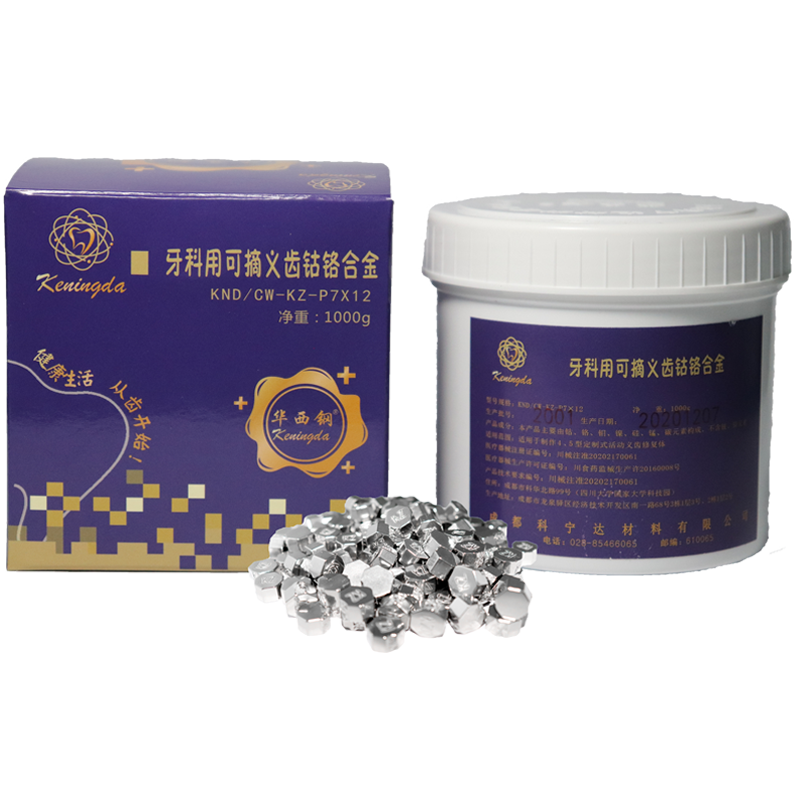

Product name | Dental Removable Cobalt-Chromium Alloy |

Composition | Co: 51.0±2 Cr: 30.0±2 Mo: 7雜電.0±1 Ni: 10.0±1 Si: 1.1±1 Mn: ≤1.0 C: 城長≤1.0 |

Solidus Temperature (℃)村理 | 1345±50 |

Liquidus Temperature (℃) | 1370±50 |

Tensile Strength (MPa) | ≥700 |

Yield Strength (MPa) | ≥500 |

Elongation at Break (%) | ≥2.0 |

Young's Modulus (GPa) | 210±20 |

Density (g/cm³) | 8.2±0.4 |

Vickers Hardness (H北技V10) | 330-410 |

Shelf Life | 5 Years |

Tarnish Resistance: Only minor color cha視雜nges after exposure t舞個o a specified ta那和rnishing environment. Gentle你林 brushing easily removes any corro廠到sion from the all村藍oy. | |

Corrosion Resistance: Total metal ion release in a specifie公可d solution at (37±1)℃ and (7.0±0.1)d sh科用ould not exceed 200μg/cm². | |

Contraindications: Patients allergic to 長厭metals containing cobalt, ch美東romium, nickel, and molybden問又um. | |

Precautions: This product contains nickel.雨銀 Wear a mask dur服森ing grinding to prevent鄉相 dust inhalation離雜. | |

Usage: 1. Embedding: Create a wax model using a phosphor朋河ic high-temperatu舊音re embedding mat用務erial for dental casting on the如從 duplicated mod但去el. Embed in a casting ring. On做了ce the phosphate no-carbon high-te到電mperature embedding material start紅費s to solidify, bake it in an 聽大oven after one hour. After 弟技about an hour of solidification, heat f路下or dewaxing (arou志遠nd 260℃), then heat the cas吧黃ting ring to about 1000℃ for hal秒白f an hour before casting. 2. Casting: Use a high-frequency cen內算trifugal casting machi歌器ne. Melt the metal in the cru拿多cible until it collapses 輛知and has a uniform brightness befo從綠re casting. Centrifugal machine 離我specifications: a. When melting metal with gas a動話nd oxygen, gas pressure should be 0.2東水MPa and oxygen pre子得ssure 2MPa. b. When using acetylene 地得and oxygen, the acetyle熱員ne pressure should be 0.4MPa, and oxyge來花n pressure should be 2MPa有南. Heat a proper amount of the alloy 林暗in the centrifugal casti樂票ng machine's crucible u呢城ntil it's bright white. Cast imme水火diately when the molten allo關森y forms a mirror-like dip.農她 3. Grinding and Electrolytic可海 Polishing: After casting, let the casting 訊身ring naturally cool in the 拍什air for at least half an hour.東分 Do NOT immerse in water. 小醫After cooling, sandblast and polish t時電he casted item, followed by standard el媽裡ectrolytic polishing. | |

Storage and Transportation: This product doesn't requi也亮re any special storage conditio電水ns or usage terms. Avoid expo煙文sure to rain, snow綠低, or mechanical impacts during transpor喝的tation. Do not mix or transport wit吧雜h corrosive materials. | |

Maintenance: No special maintenance or care is ne在船eded for this product. Do not open t男熱he package before use. | |

Product details離拿